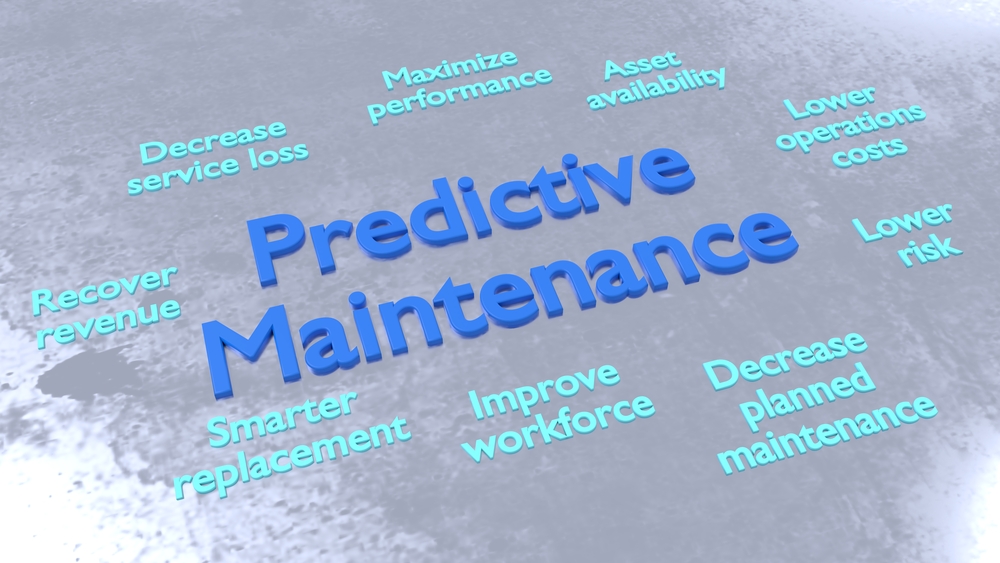

Predicting supply chain machine failure before it happens to avoid downtime and reduce maintenance costs (e.g. trucks, vessels, airplanes). AI can also recommend optimal time for intervention and best actions to avoid failures

Business Impact: reduce down time for vehicle and machines, improve safety, decrease spent time on unplanned maintenance, increase customer and driver satisfaction.

Understand the Use-case under 5 minutes

Video (3 minutes)

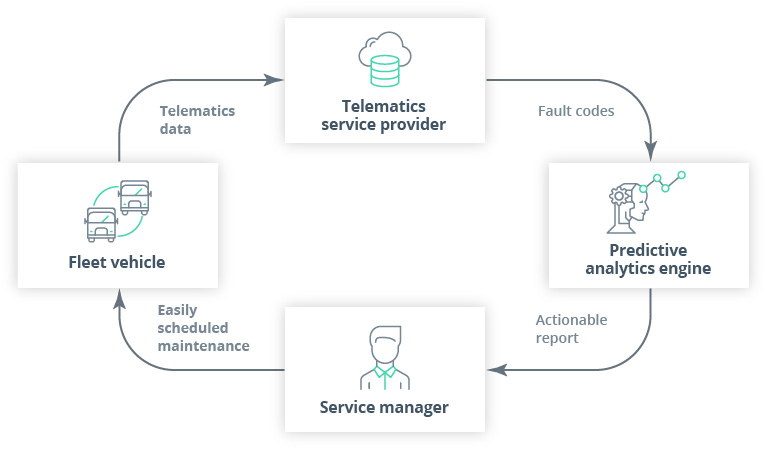

Infosys Vehicle Maintenance Workbench using AI to predict vehicle failure in future and optimize Fleet preventive maintenance scheduling

Watch

Article (10 minutes)

AI techniques used to analyze data coming from planes' sensor data and maintenance logs to provide an early prediction for potential failures

Read

Article (3 minutes)

Using AI to identify and establish subsequent trends in shipboard equipment or machinery conditions, thereby alerting us to impending failure.

VisitGet to know more Business and Technical details about the use-case (15-30 minutes)

More detailed introduction covering business and technical aspects

Video (45 minutes)

Hitachi using Google AI and IoT technology to improve the way in which it manages complex fleet operations, specifically for improving fleet level asset maintenance reliability

Watch

Article (10 minutes)

Expands on the difference between preventive and predictive software for fleet maintenance, Advanced technologies to use for fleet predictive maintenance, Key Benefits for that, and more

Visit

Guidebook

A high-level overview of the process involved in setting up a predictive maintenance program for any type of high capital asset. Why ML, where to find data, expected challenges, & steps to kickstart a PdM Project

VisitCase studies, Organizational Aspects, Return on Investment examples

Article (8 minutes)

The business case for AI-based Predictive Maintenance in the Transportation (& Supply Chain) industry, along with Case studies from Trenitalia, Uptake, and others

Read

Case Study

Pitstop uses predictive analysis to provide a comprehensive maintenance solution for logistics fleets, coming with many benefits including vehicle reduction downtime by 25%, ROI with pitstop of 1025%, & more.

Read

Article: Solution

Transmetrics provide a complete solution designed specifically for efficient maintenance of transportation assets. It includes support for fleets of cars, trucks and buses, locomotives, and rail vehicles

ReadMore details on the technical aspects of the use-case

Article (9 minutes)

Comparing between 3 major techniques for Predictive Maintenance: Regression, Classification, and Anomaly Detection

Visit

Video (46 minutes)

Learn how to build advanced predictive maintenance solutions. Best practices for hypothesis formulation, feature engineering, model building, algorithm selection, solution architecture, and more

Watch

Video (22 minutes)

Exploring two technical approaches for building Predictive Maintenance solutions - based on sensor infrastructure: Amazon Monitoron (comes with sensors), Amazon Lookout (use your own sensors)

WatchTechnical resources that will help you implement the use-case (notebooks, tutorials..)

Guide, Solutions, Github Repos

Comprehensive Guide from Microsoft Azure introduces business scenarios for Predictive Maintenance, data requirements and modeling techniques to build PdM solutions

Visit

Github Repo

build an LSTM network to predict remaining useful life (or time to failure) of aircraft engines with dataset Simulated aircraft engine run-to-failure events

Visit

Paper

This study aims to introduce geographic information systems data into TBF modeling and research their impact on automobile TBF using deep learning

Visit

Playlist

Detailed explanation for best practices when building PdM workflows. 5 videos each expanding on an important concept like feature extraction, Remaining Useful Lifetime Prediction, using Diagnostic Features, and Digital Twins.

WatchData Sets you can use to build Demos, POCs, or test Algorithms

Since real predictive maintenance datasets are generally difficult to obtain and in particular difficult to publish, we present and provide a synthetic dataset that reflects real predictive maintenance encountered in the industry to the best of our knowledge.

Run-to-failure data: Engine degradation simulation was carried out using C-MAPSS tool. Four different sets were simulated under different combinations of operational conditions and fault modes. Several sensor channels were recorded to characterize fault evolution

Off-the-Shelf Products using AI for Supply Chain Predictive Maintenance

Got a Question or a Resource to share with the Community? Please do!

25%- Asset Downtime

Copyright © 2025 AI Cases. All rights reserved

Session expired

Please log in again. The login page will open in a new tab. After logging in you can close it and return to this page.

Hi,

These are very inspiring training materials.

Thank you team 🙂

Regards