Deep Learning models can be used to detect and localize the defects in images creating a visual inspection system. This system can notify employees about defective parts on production lines. Automating quality inspection reduces cost of production by saving time and increasing throughput, increases employee safety and improves the quality of the products.

Understand the Use-case under 5 minutes

Video (3 minutes)

Exploring the main differences between classical rule-based machine vision systems and deep learning, for manufacturing - and why the latter usually provides higher accuracy and portability

Watch

Video (1.5 minutes)

How defected products cost corporations significant amount of money, and the role of AI in providing more reliable and automated quality inspection process

WatchGet to know more Business and Technical details about the use-case (15-30 minutes)

More detailed introduction covering business and technical aspects

Article (14 minutes)

5-Steps Guide for implementing AI-Visual Inspection: State the Problem, Prepare Data, Train DL Model, Evaluate, Deploy & Optimize. Included Case Studies: Automotive, Computer Equipment, Textile, & more

Visit

Article (13 minutes)

A nice comprehensive intro about AI-VI: when is it needed, why not just stick to traditional methods, what is machine vision, how does it go hand in hand with AI, how to get started: software, hardware, & resources needed

Read

Video Case Study (30 minutes)

Session at the International Maintenance Conference. How does Machine Learning apply to PdM today, and how to effectively launch a ML-based PdM program. Digs into some technical aspects like feature engineering and types of modeling

WatchCase studies, Organizational Aspects, Return on Investment examples

White Paper (12 minutes)

Obstacles and Resolution Best Practices: Limited Clean Data Sets, Ambiguous Defect Requirements, Changing Environments and Requirements, Compounding Complexities

Read

White Paper (15 minutes)

Landing.AI conducted a study that will walk you through the problems of traditional inspection, the projected solutions, the ROI, and the challenges from the perspective of some 110 companies

ReadMore details on the technical aspects of the use-case

Video (27 minutes)

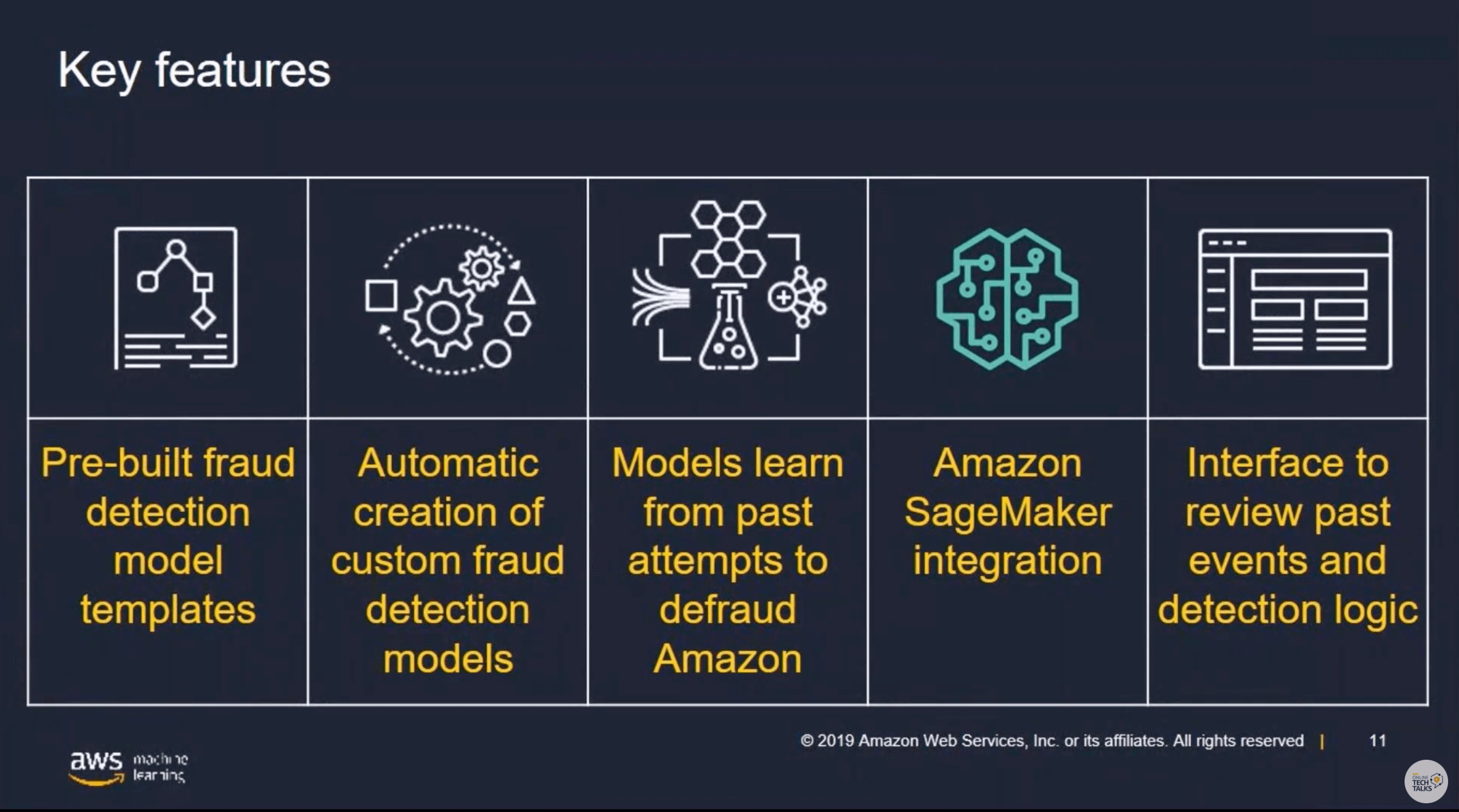

Lookout for Vision is an AI Service from AWS that provides: simplified labeling, trial anomaly detection & feedback, quick model evaluation, Manufacturing line integration, and more

Watch

Video (5 minutes)

See how Visual Inspection AI will help you transform production Quality Control by automatically detecting product defects and deliver significant ROI for real use cases in discrete manufacturing

WatchTechnical resources that will help you implement the use-case (notebooks, tutorials..)

Cloud AI Service

Different resources to learn about and get started with AWS Lookout for Vision: Homepage, Documentation: how to use and step by step guide, Solution Demo configurable on AWS, and Code-first Github Sample

Visit

Cloud AI Service

AI Service from Google providing Purpose-built, deep learning models for high-precision manufacturing inspection. Features: quick start with GUI, minimal labeling effort, run at production lines via Docker, & more

Visit

Article (15 minutes)

A combination of pure computer vision approach (non-machine learning methods) to extract the region of interest (ROI) from the original image and a pure deep learning approach to detect defects in the ROI

Visit

Kaggle Notebook + Data

Building a model that detects Defects in Casting Products: holes, burr, shrinkage, mould material defects, and more. Performing model interpretation by using SHAP

Visit

Github Repo + Paper

Automating Quality Control using AI-based visual inspection to distinguish between defective and non-defective products. Implementing the model proposed in this Paper

VisitData Sets you can use to build Demos, POCs, or test Algorithms

Weakly Supervised Learning for Industrial Optical Inspection. This is a synthetic dataset for defect detection on textured surfaces.

Casting Products Defects. 7348 images annotated as “Defective” or “Ok”

Off-the-Shelf Products using AI for Visual Inspection

Got a Question or a Resource to share with the Community? Please do!

Copyright © 2024 AI Cases. All rights reserved

Session expired

Please log in again. The login page will open in a new tab. After logging in you can close it and return to this page.